Step One

Annealed brass cups are made in the USA to NAT specifications and quality standards. Cups are inspected on our Rockwell hardness scale machine before entering the case forming unit (CFU).

Step Two

Brass cups are drawn in our case forming unit at a rate of (240) cases per minute. Custom head stamp tooling is designed and manufactured at our facility. All cases are manufactured to SAAMI specifications.

Step Three

Brass cases then enter wash station number one. Here, cases are washed and dried using new machinery with an automated timing and solution system.

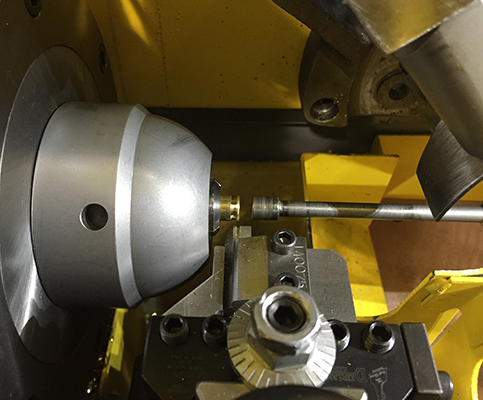

Step Four

Cleaned and dried cases are placed in the elevator hopper. The elevator hopper feeds each head turn machine using multiple sensors. Extractor groove is cut on the head turn machines.

Step Five

Finished cases are loaded into NAT’s proprietary bowl feeder and meter system from an automated elevator hopper for laser and vision inspection. Our OPTO 22 systems monitor and control each step of the process. Every case is inspected with dimensions documented and stored by lot number to maintain quality controls. Inspection tolerances are derived from MIL-STD-636.

Our 360 degree laser inspection station ensures every case meets these requirements:

- Overall Length

- Mouth Diameter

- Groove Length

- Groove Diameter

- Rim Thickness

- Head Diameter

Vision Inspection Station

- Primer Pocket Diameter

- Flash Hole Diameter

- Head Stamp Presence

Step Six

Cases that pass inspection to SAAMI specifications are washed, dried and dipped in an inhibitor wash to maintain a bright and clean appearance.

Step Seven

Cases are placed in 5 gallon pails lined with 4 mil bag for protection. Each pail is placed in double cardboard box to minimize shipping damage. Each 5 gallon pail is sealed with up to 8,000 quality cases inside.